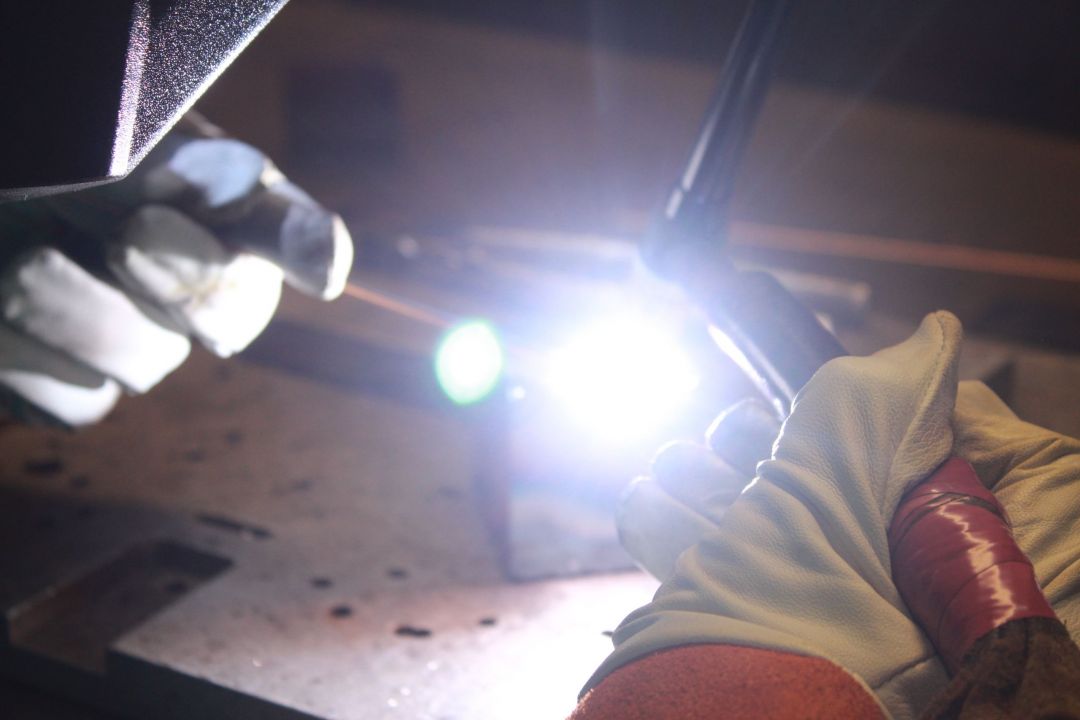

WeldingMetal

TIG Welding 101: Everything You Need To Know Before Learning TIG Welding

By Kristin Arzt

TIG Welding 101: Everything You Need To Know Before Learning TIG Welding

TIG Welding is a highly precise and versatile method of welding that allows you to weld a variety of material sizes and types. It is a great option for welding non-ferrous metals together. Compared to other types of welding, TIG takes more time to master, making it a slower process with a greater production cost. The Crucible’s Welding Department offers classes in four different types of welding, so do some research and become familiar with the different types of welding before you start.

What is TIG welding?

TIG welding, which stands for Tungsten Inert Gas, is a precise welding process that is used for projects with thinner materials. Also known as GTAW (Gas Tungsten Arc Welding), it is the type of welding commonly used for delicate work and non-ferrous metals. It uses an AC/DC power source, a non-consumable tungsten electrode, and inert gas to form an arc and create a weld.

TIG vs MIG welding

TIG and MIG welding both use an arc to create heat and weld metals together, but they differ in the way that the arc is used during the welding process. TIG (Tungsten inert gas) welding uses a tungsten electrode that produces an electric arc between the torch and the materials. The TIG welder uses a foot pedal controlling the arc length, one hand supplying the sacrificial rod, and the other hand aiming the electrode at the work surface. On the other hand, MIG (metal inert gas) uses a wire welding electrode that consistently moves through the welding machine on a spool. TIG is a slower process to learn than MIG because it takes longer to learn and is not forgiving of common mistakes. TIG produces more precise welds on a variety of metals, while MIG is limited to thicker metals.

TIG welding applications

TIG welding is a practical and useful skill with incredibly vast applications. TIG is the most versatile type of welding in terms of the metals you can weld. It can be used on steel, bronze, titanium, copper, aluminum, stainless steel, Chromoly, nickel alloys, magnesium, brass, and even gold.

TIG is a useful process for welding:

- Bike frames

- Pipe welding

- Wagons

- Lawnmowers

- Door handles

- Airplanes

- Automobiles

- Spacecrafts

- Medical and scientific equipment

How TIG welding works

TIG welding works by generating heat between the metals to be joined and an infusible tungsten-based electrode, which is located in the welding torch. The arc area is shielded in gas to protect the weld pool and the tungsten electrode from oxidizing.

Constant current power source

TIG welding uses a power source that maintains its current at a constant level. The voltage, which can change drastically, is powered through the foot pedal that controls the arc length. The constant current compensates for changes in the arc length.

Starting the arc

When you are first powering up the wedding machine, start the arc on a piece of metal by striking it like a match. First, turn the gas on the torch. Then, make a small sweeping motion with your torch to make contact between the tungsten tip and the metal plate. The arc will initiate automatically.

Electrodes

The electrodes used in TIG welding are made of tungsten because of their heat resistance and conductivity. Because the electrode is non-consumable, it can get worn out from use. Ideally, a tungsten electrode has a pointed tip. The tungsten electrode is maintained at an ideal shape so that it can effectively point the electric arc towards the work surface. Depending on the type of work material and thickness, the electrode can vary in alloy combinations.

Shielding gas

Shielding gas is supplied through the weld gun to ensure that the weld pool does not oxidize the weld area. Argon is a noble gas and the most commonly used shielding gas in TIG Welding because it is easily accessible and easy to control. Helium can also be mixed in to increase penetration and expand the shielded area, though it is a more expensive gas than argon.

How to learn TIG welding

Once you are sure that you want to learn TIG welding, you can begin to plan out your projects and educate yourself on different ways to learn. We recommend first enrolling in local classes to learn TIG welding in person from a professional. When you have the fundamentals down, you can start to weld on your own or enter the field as a professional welder. Since TIG welding is one of the more challenging forms of welding, many students will learn a more introductory type of welding to start, then graduate to learning the techniques necessary to successfully TIG weld.

Know your goals

There are many possibilities when you are first learning how to TIG weld. First, plan out your projects in advance and become clear on your goals. If you are a gardener, you may want to explore creating sculptural artwork for your yard. If you are a biker, you might find great fulfillment in TIG welding your own bike frame. With enough practice and technical skill, TIG welding can also be a pathway to a lucrative career.

Take local classes

There are a few different ways that you can learn TIG welding in a class setting. When you are first starting out, learning from a professional is the safest option and will likely save you time in the long run. Some high schools and community colleges offer vocational programs.

The main certification employers will require is passing the basic American Welding Society Certified Welder test, which you can take at any accredited testing facility. If you are interested in pursuing welding for personal projects, or simply want to explore which type of welding is right for you, you do not need to become a certified welder. For those local to the Bay Area, The Crucible offers a vast range of welding classes that are open to the public with a variety of options based on your experience, schedule, and interest.

TIG Welding at The Crucible

If you are looking to weld non-ferrous metals, The Crucible’s TIG Welding classes will be your best choice. TIG welding is often described as using a sewing machine to weld, and involves both hands and a foot pedal. Using cold-rolled steel, The Crucible’s TIG Welding class begins with a series of small exercises and progresses into a challenging technical project, giving you a foundation in basic metallurgy, preparation, joints, technique, and safety.

The Crucible teaches beginning and advanced classes in four different kinds of welding: oxy-acetylene gas welding, arc or stick welding, MIG welding, and TIG welding. Start with a beginning class in MIG welding, or sample all four types in our Exploring Welding class. The Crucible also offers beginner and advanced level TIG welding classes, which will introduce you to working with a variety of materials. In an ARC welding class, you will learn how to use an electric arc to create heat to melt and join metals. ARC welding is a great method for advanced joints and welding positions. The Crucible’s Oxy-Acetylene welding class teaches you to weld with heat produced by burning gases. Oxy-acetylene is one of the most versatile types of welding. You can use it to weld iron or steel, and also use heat to cut, braze, and weld metals. It comes in handy for removing rust or scale from metals, and for loosening corroded nuts and bolts.

TIG welding FAQs

Is TIG welding hard to learn?

TIG welding is known as one of the hardest types of welding because it requires more coordination and practice than other forms of welding. The process includes a foot pedal controlling the arc length, one hand supplying the sacrificial rod, and the welder’s other hand aiming the electrode at the work surface. It takes more time to learn the fundamentals, making it a slower process than other types of welding.

Can I teach myself to TIG weld at home?

Because of the technical skill required for TIG welding, it is best to learn the process in a controlled environment with a professional welding instructor present. Save time and money in the long run by learning in a class with a welding teacher, rather than teaching yourself. It can be costly to set up your own welding studio at home, so beginning in a professional space is advised. It is safer to practice in a well-ventilated studio that has the proper equipment in place.

Do I need a welding certificate from a program or school?

You do not need a welding certificate or license to start welding. You can learn to weld in public classes, like those offered at The Crucible. Many students who are interested in pursuing welding as a career start out by taking a class at The Crucible to determine whether or not they want to commit the time to a full program. The Crucible is not an accredited welding program and does not provide licenses or degrees upon completion of welding classes at The Crucible.

If you are interested in working in welding as a career, there are a number of certifications and licenses offered that employers may require. American Welding Society is a great resource for learning how to get certified. You can also enroll in and complete a welder’s training program at a vocational school or local community college. If you are local to the Bay area, Laney College offers an excellent certification program.

What type of welding is the strongest?

The strongest welding type depends on the type of metal, material thickness, and anticipated weight load. TIG welding produces the cleanest welds with the least amount of splatter. This is because a larger amount of filler metal goes directly into the weld joint. It is also ideal for thinner materials that require more precise welds. MIG welding provides the most consistent welds and is the easiest type of welding for beginners to learn. Flux Welding creates the strongest welds in thicker materials, however the filler material is more expensive than other welding types. The flux core wire allows the weld to cool more slowly, which creates a more consistent and stable weld joint.

How much do welders make?

The average hourly pay for a welder in the United States is $17.60, which adds up to around $45,000 a year. More experienced welders can make as much as $35 per hour. Specialty welders can earn anywhere from $50,000 to $200,000 annually. Traveling industrial pipe welders earn up to $185,000.00 a year, and underwater welders can earn over $200,000 annually.

MIG vs TIG vs Stick, which is best?

There is no best type of welding. The type of welding that will work best for you is relative to your experience, materials, and project. MIG welding is generally the easiest to learn for beginning welders. TIG welding is a slower, more precise process that works with many different types of materials. Stick welding produces strong welds on thick materials and can operate outdoors and underwater, making it a very versatile process.