by Natasha von Kaenel

On Friday night, our Foundry Department came together for The Crucible’s 20th Anniversary Iron Pour, casting over 1000 pounds of molten iron into a variety of ceramic shell and resin-bonded sand molds. Crucible staff, faculty, Foundry community members, and students worked to pull off the elaborate dance it takes to cast iron pieces, including quickly problem solving at the beginning of the pour. The slag at the opening of the furnace had cooled and solidified, blocking the iron from coming out of the tap hole. Instructors used an oxygen lance to heat up and clear the frozen tap hole, and then the pour began!

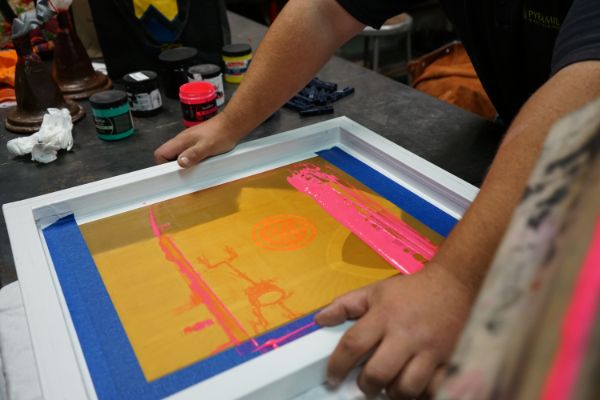

For the sixteen students enrolled in Iron Casting and Design and Make Your Own Waffle Iron, this was their first opportunity to pour iron alongside The Crucible’s Foundry Department. Their final projects will be revealed in two weeks, once the students have cleaned them up, grinding the sprues and completing any desired finishing work.

Our generous donors, staff, faculty, volunteers, and past Foundry students came out to witness the department at work, and got a spectacular reminder of just the many cast iron objects that surround us daily are created.

“The iron pour itself was really exciting and spectacular,” said Chris Thorson, a Crucible volunteer and CREATE Member in the Foundry Department.

“It’s nice to be reminded of how things are made. The products of industrial process are around us every day. When you actually see how the physical forces of heat and iron work together on a very small scale, it changes your perspective and it can inspire and empower you to be a maker.”

As the Foundry Department worked to transform iron from solid to liquid, members of our Blacksmithing Department worked alongside them, smelting small particles of iron into one solid form.

Thanks to everyone who came out for the fun, see some of our favorite photos from the night below.