Community

Please Join Us In Welcoming New Machine Shop Department Head, Ian Wenck

Cathy Niland | 07.21.2021

At age 17, an eager High Schooler named Ian Wenck got a waiver to take an adult Blacksmithing class at The Crucible. On his way to the Smithy he passed the Machine Shop and was immediately intrigued.

“I stumbled into machining about 10 years ago and had a realization like, ‘Oh, that’s how it’s all made.’ Then I started saving up money and went out and bought my own mill and a lathe,” Ian shared. “I studied machining independently for five or six years, then went through the Diablo Valley College program.”

Ian Wenck’s passion shines bright on The Crucible Machine Shop and beyond

Over a decade later, Ian has found his way back to our Machine Shop as our new Department Head. His passion for machining is contagious and his love of problem-solving makes him a perfect fit for the job.

But it’s not just Machine Shop where Ian shines. He’s spent much of this summer instructing youth students in TIG Welding, a skill set he often uses in his own work. He’s also passionate about wheel-thrown ceramics, and has worked in Foundry and Jewelry. His wide breadth of industrial art knowledge comes in handy when departments need a part to be fixed or created.

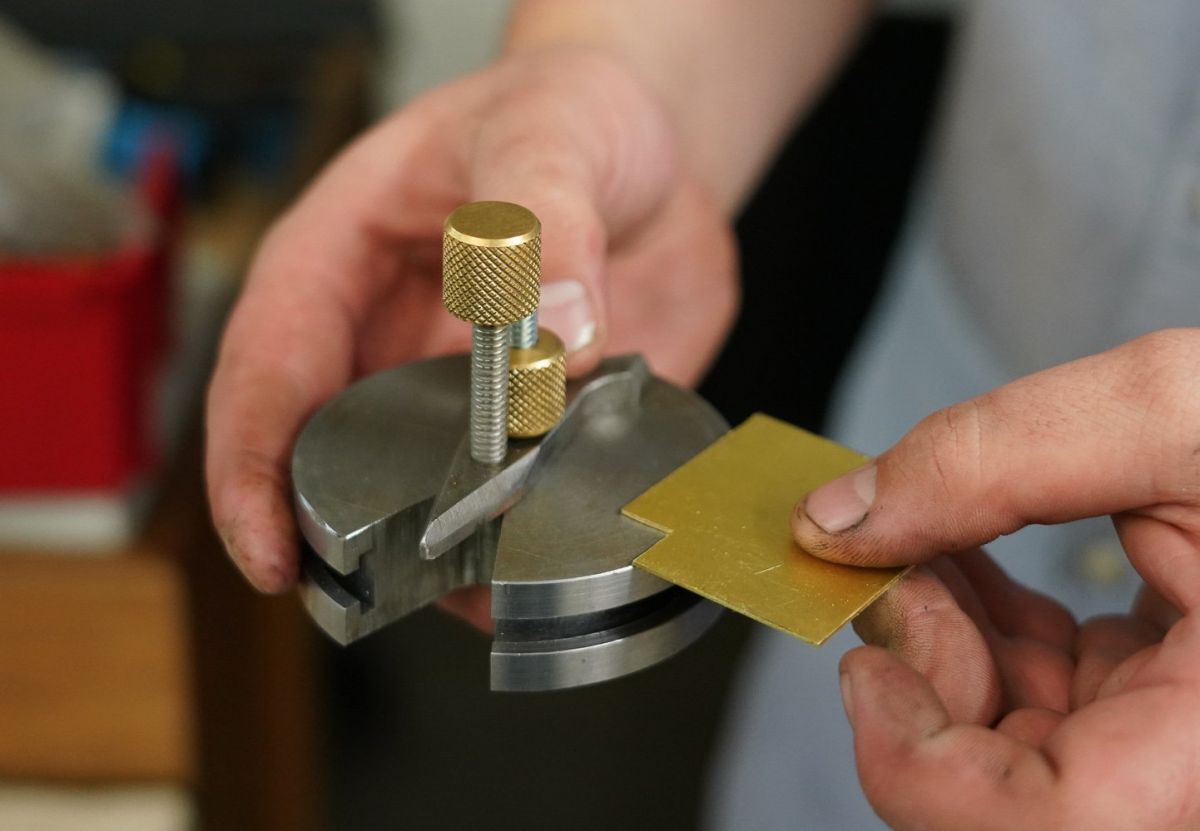

Ian shows off the work plate he designed for our Jewelry department.

“A good part of my week is, ‘Ok, this is X-problem, how can we solve that?’ I’ve been working with the Jewelry department to create a small work plate. It has a clamping finger that holds things while you do small work like sawing. Having an in-house shop is a portal for making things happen.”

Following in the footsteps of his machining ancestors

While he never had the pleasure of meeting his predecessor Ken Gilliland before his passing earlier this year, Ian is dedicated to carrying on the traditions of the old Machine Shop guardsman. “I love those guys, they have so much knowledge. We have what we call the Machinery Handbook and most of these guys have all that knowledge in their heads.”

So while Ian hopes to expand the Machine Shop’s offerings in the coming months and years, he also wants to remain true to machining’s origins.

“I want the shop to very much keep its roots as a manual machine shop,” Ian explained, “And also update the program to reflect where machining is going as a whole with computer-controlled machines. I want it to be a machining and manufacturing program.”

While Ian works to expand our Machine Shop he hopes you’ll join him in a class to learn how things are made. Like Ian says, “Anyone and everyone is welcome in the Machine Shop.”